STEP IN - SGRATE FIBERGLASS REINFORCED PLASTIC GRATING & STRUCTURALS

Step In technologies Gratings are of Fiberglass Reinforced Plastic products, Our exclusive FRP systems offer the highest quality product available on the market today. FRP is used in a variety of Residential, Commercial, and Industrial settings from Oil and Offshore, Chemical Processing Facilities, Food Processing Plants to Pedestrian Bridges, Decks & Walkways. Our engineers are ready to assist you with your project needs. From supplying panels to turn-key projects.

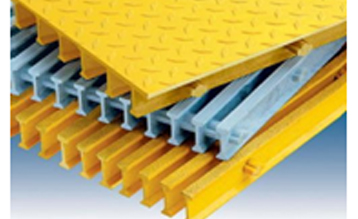

MOLDED FIBERGLASS GRATING – MFG

MFG is constructed in one-piece, using reinforced polyester, Isophthalic or vinyl ester resin and continuous interwoven fiberglass strand. This gives it multi-directional strength and allows for fabrication such as holes, cut-outs, without losing any structural integrity. It's used for flooring systems, walkways, trenches, platforms, stairs and much more. Customers can choose from a variety of sizes, such as 4' x 12', 4' x 8', 3' x 10', 5’ x 10’ and thicknesses such as 1", 1-1/2", 2”. Moulded grating is easy to fabricate. You can custom fabricate or we can fabricate panels to size for you.

PULTRUDED FIBERGLASS GRATING- PFG

PFG is ideal for longer spans and slightly lower in cost than Moulded Grating. Its high load bearing strength makes it uniquely popular for spanning long distances. STEP IN grating uses a two part locking cross rod and features powerful uni-directional strength. The individual bars are made of glass roving and glass mat which gives it its strength. A surfacing veil provides high corrosion resistance. Used for flooring systems, walkways, trenches and platforms, customers can choose from a variety of sizes such as 3', 4' or 5' wide by 8', 10', or 20' lengths. Standard thicknesses are 1", 1-1/2", and 2", I bar or T bar are available

VINYL ESTER (Type V):

Developed to withstand frequent and direct contact in the harshest of chemical environments. Type V is ideal for use in acidic and caustic environments, such as chemical plants, waste water treatment and plating applications.

ISOPHTHALIC POLYESTER (Type I):

An industrial grade resin great for environments where grating may occasionally be in contact with harsh chemicals due to splashes or spills.

FOOD GRADE ISOPHTHALIC POLYESTER (Type F):

Ideal for environments in the foof and beverage industry where grating may frequently be wet or exposed to harsh cleaning products.

GENERAL PURPOSE POLYESTER (Type GP):

A lower cost resin ideal for environments such as food processing plants and dairies,

EXTRA FIRE RETARDANT ISOPHTHALIC POLYESTER (Type XFR):

Offering an added level of fire safety for critical areas where welding or sparking equipment is used or anywhere with increased fire potential.

PHENOLIC (Type P):

Best choice for applications where fire resistance, low smoke and low toxic fume emissions are critical such as oil refineries, tunnels, ships and train decks.

COLOR SELECTION:

Standard grating colors are Green, Yellow, Light & Dark.

Custom colors are available on request for an additional charge using the RAL Color Chart.

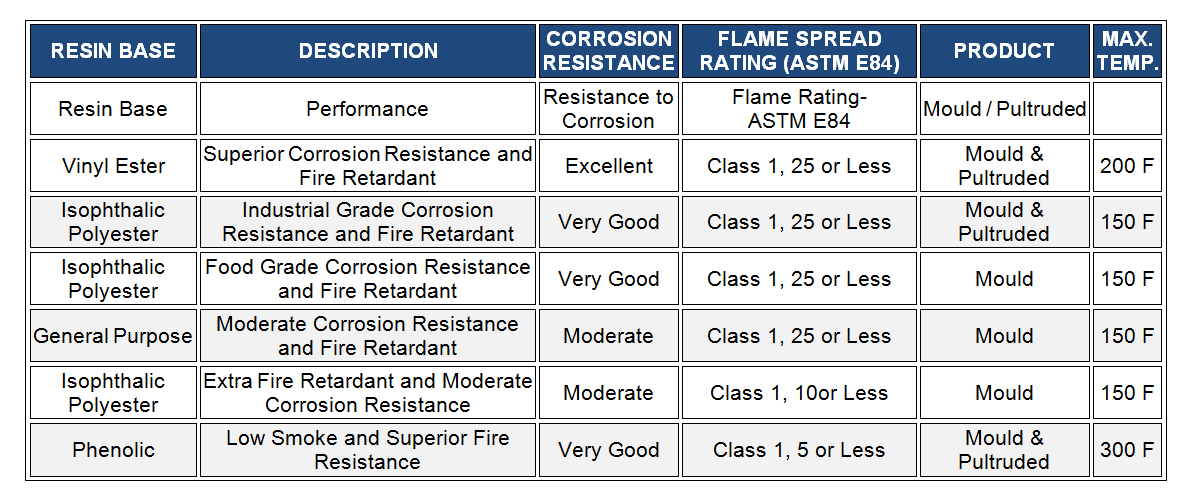

RESIN SELECTION GUIDE

Resin Selection is the very vital part on FRP Gratings – As in Competitive Market STEP IN ensures to

select a correct Quality product in Economical & Technical way to our customers…

This Enables our customers to have comparison with competition which Now a days use OIL MIXED RESINS to offer a price reductions – This will shortens the FRP performance and in some cases its Life Threatening.